|

|

|

|

|

Reaction Bonded Silicon Carbide Wear Parts

|

|

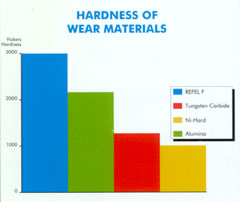

Wear Resistance

There are many possible modes of wear, however generally these can be categorised under two headings, erosion and abrasion. To combat wear, a material requires a combination of hardness and fracture toughness.

REFEL has a greater hardness than other ceramic materials commonly available. In addition the fine grain structure of REFEL produces substantially higher fracture toughness values than other silicon carbides.

|

|

|

|

|

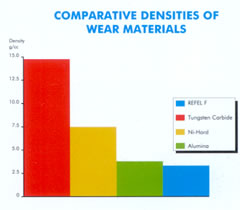

Light Weight

REFEL has an extremely low density which allows the component weight to be minimised. This is particularly important on rotating machinery where balancing is required.

|

|

Thermal Resistance

With a minimal coefficient of thermal expansion combined with unsurpassed thermal shock resistance, REFEL is ideal for those demanding applications where other ceramics do not perform.

|

|

|

|

Typical Applications or Typical Wear Ports Available in Refel

|

|

- Cyclone components

- Hydro cyclone components

- Centrifuge wear tiles

- Shot blast nozzles

- Spray nozzles

|

|

- Fluidised bed dryer components

- Burner nozzles

- Pipe Linings

- Coal Injection Bends

|

|

|