|

|

|

|

Introduction

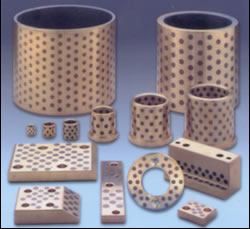

Maintenance-free bearings are important for modern designed machines.

Maintenance-free FEROLUBE- bearings made for heavy bearing load at low sliding-speeds.

They are specially made for those applications, where no liquid lubricant can be used. Normally, the lack of the lubricant would cause constant contact of shaft and bearing. This would

result soon damage of both parts. Therefore FEROLUBE- bearings with solid lubricant are used in above

mentioned cases, when security and reliability are needed.

|

Operation

Also surfaces, which seem to be smooth are rough and not plain. If bearing is working without a constant

lubrication, the surface of the bearing and the shaft will be damaged. This will lead to a higher friction

and to higher wear-rates.

If using a liquid lubricant, there will be build up a lubricant- film only at higher sliding-speeds. This

film will separate shaft and bearing , so that no wear will occure.

|

|

|

When using FEROLUBE- bearing, the solid lubricant in the bearing will smoothen the roughness of the surfaces

and separate shaft and bearing, This will also work at heavy bearing- loads, low sliding- speeds and temperatures

up to 4500C . To warrant these function from the beginning of operation, FEROLUBE- bearings are delivered with an additional

lubricant film.

The basic material of FEROLUBE will be chosen accordingly to your needs.This material, mostly copper-alloys, will be

equipped with solid-lubricant suitable for your application. During the sliding-process, the lubricant will cover the shaft-surface and assure a maintenance -free running. Small particels of dust, abrasion etc. will move into the lubricant-dots and

be replaced through the same amount of lubricant.

The frictional heat cannot be lead away through the lubricant like in other bearings. For this reason the sliding-speed must be limited.

|

|

|